Knitting machines have transformed the Indian textile and garment manufacturing industry by making the process faster, more accurate, and scalable. Whether you’re a small-scale manufacturer, an industrial unit, or a design lab, choosing the right knitting machine can make all the difference in quality and efficiency.

Here’s a curated list from Bharat Machinery works the largest Knitting Machines manufacturer in India brings you 10 best knitting machines in India, ranked by how useful and versatile they are in real-world usage. We’ve also included 7 key types of machines most commonly used across India.

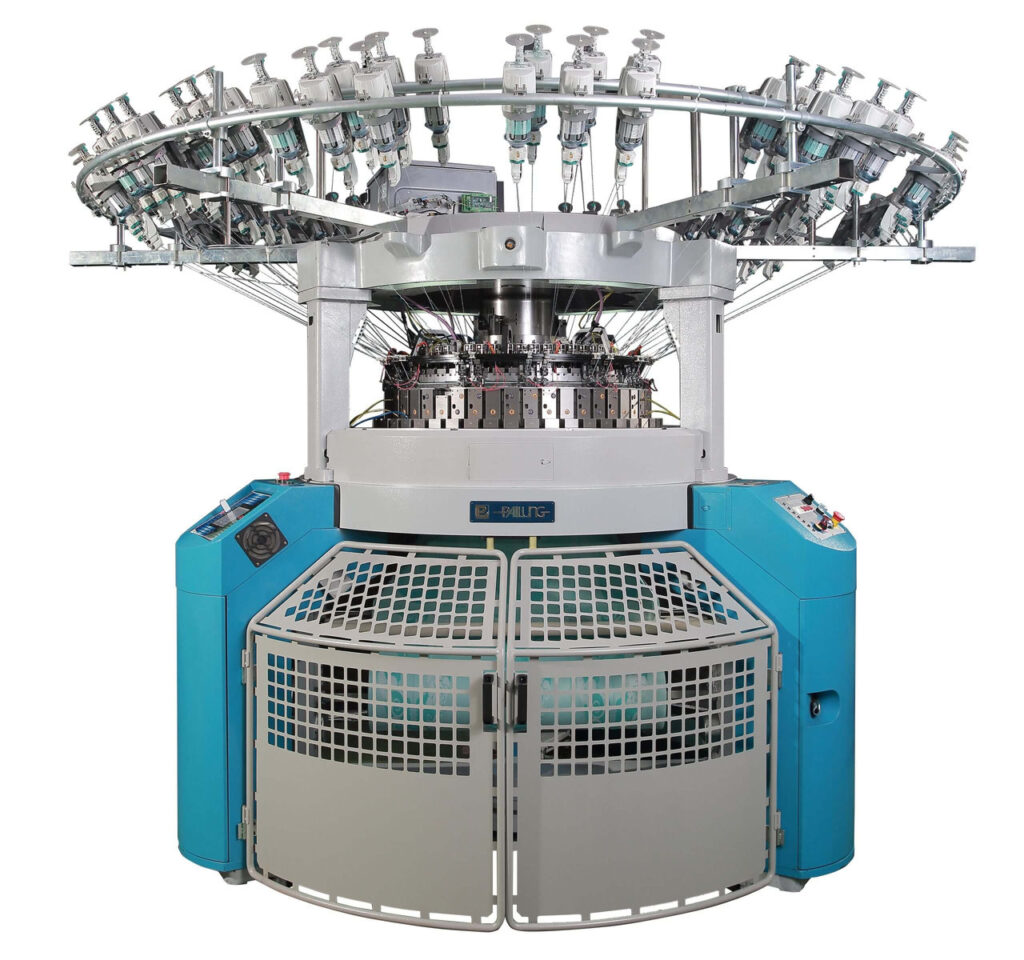

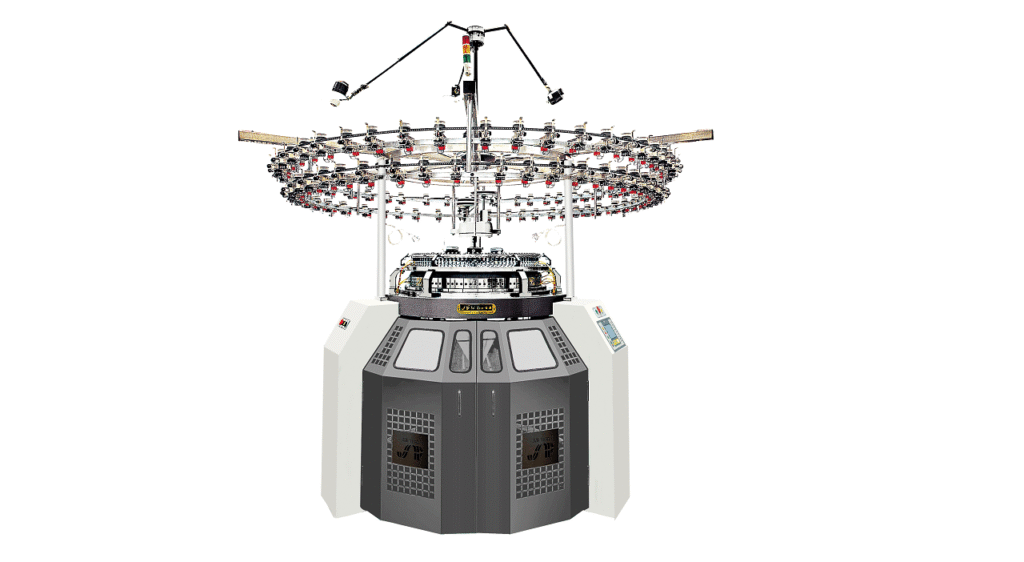

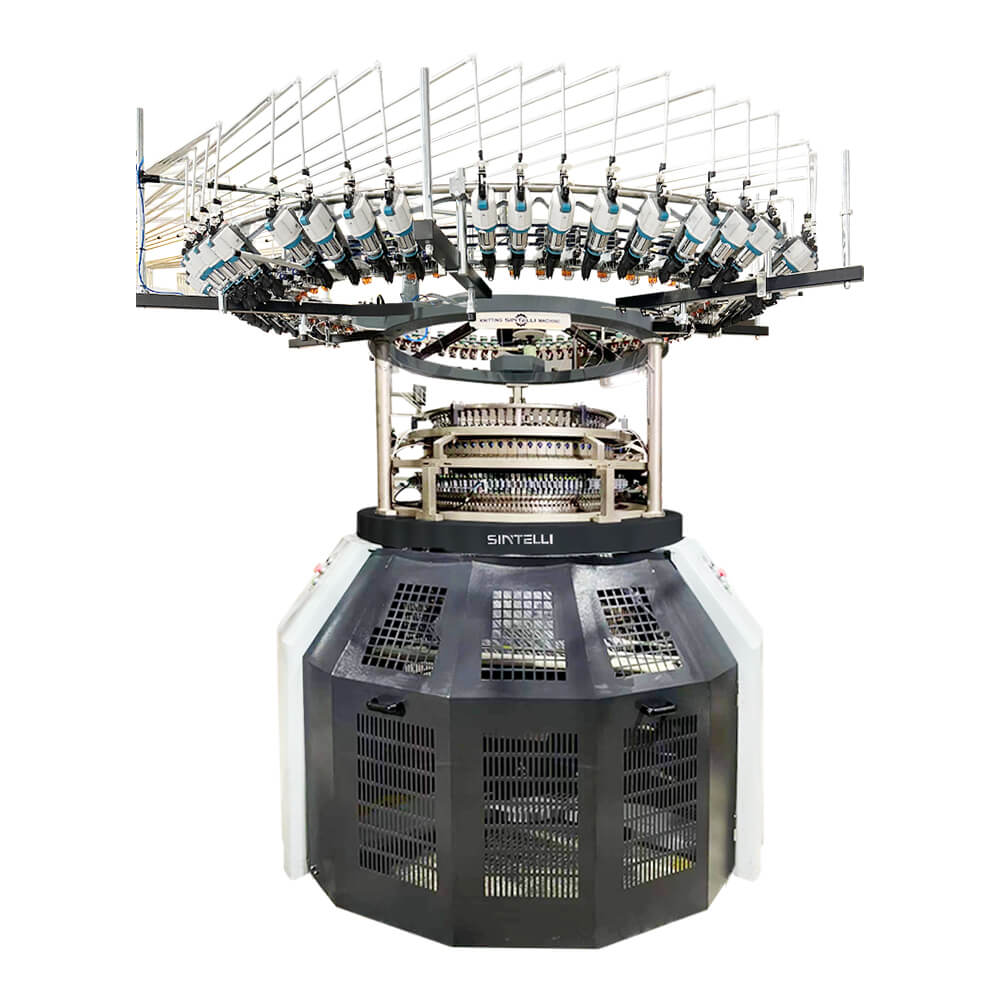

1. Circular Knitting Machine – Best Overall for Mass Production

If you’re looking for sheer speed and volume, Circular Knitting Machines are the gold standard. Widely used in the Indian hosiery and T-shirt market, these machines offer continuous tubular fabric and can handle a variety of yarns. They’re ideal for bulk garment production.

Perfect for: Large textile manufacturers

Fabric Types: Cotton, polyester, viscose

Feature: High-speed knitting with automatic tension control

2. Flat Knitting Machine – Most Versatile for Patterns and Custom Work

These are a favorite for fashion designers and fabricators who work with variable stitch patterns. Flat knitting machines allow greater control over complex designs and are used heavily in sweater and winter wear production in India.

Perfect for: Garment factories and boutique brands

Best for: Intricate patterns, customized designs

Bonus: Works well with heavy yarns

3. Single Jersey Knitting Machine – Best for Light Fabric Production

These are widely used for making soft, breathable fabrics like T-shirts and innerwear. The Single Jersey Knitting Machine is common across Indian mills that produce lightweight garments.

Perfect for: T-shirts, sportswear, and undergarments

Fabric Type: Lightweight, single-face knits

Edge: Simple and reliable mechanics

4. Rib Knitting Machine – Great for Stretchy and Elastic Fabrics

The Rib Knitting Machine is your go-to for producing cuffs, waistbands, and other stretchy knitwear. Rib-knit fabrics have more elasticity and are used heavily in winterwear and sportswear in India.

Perfect for: Hosiery and athletic garments

Key Feature: Dual-needle bed for ribbed texture

Use Case: Sweaters, collars, and socks

5. Interlock Knitting Machine – Excellent for Double-Faced Knits

Known for producing thicker and smoother fabric, Interlock Knitting Machines are used for garments requiring extra durability and softness. They’re a bit more advanced than single jersey machines and preferred by premium garment makers in India.

Perfect for: Premium T-shirts, baby clothes, leggings

Strength: Stronger fabric with two-sided texture

Feels Like: Double jersey fabric

6. Hose Knitting Machine – Ideal for Seamless Tubular Items

While niche, Hose Knitting Machines are still quite useful in India’s hosiery sector, especially for producing socks and stockings. These are highly specialized but essential in their segment.

Perfect for: Socks, tights, stockings

Unique Trait: Seamless circular design

Best Use: Footwear textiles

7. Lab Knitting Machine – Best for Sampling and R&D

These compact machines are mostly used by textile R&D labs or design schools to test new yarns or patterns. They’re not for mass production but incredibly useful for prototyping.

Perfect for: Educational institutions, R&D

Use Case: Yarn testing, prototype designs

Advantage: Precise control for small-batch testing

8. Computerized Knitting Machine – For Automation Lovers

These machines bring automation to the forefront and are becoming popular in India’s high-end garment manufacturing hubs. They’re programmable and reduce manual intervention.

Perfect for: Mass production with complex designs

Feature: Touch panel programming

Advantage: Repeatable quality with low error

Also Read: Who Invented the Knitting Machine? How It Has Evolved Over the Years to 2025

9. Mini Hand-Operated Knitting Machine – Best for Beginners & Hobbyists

Not everyone needs an industrial setup. If you’re looking to get started with knitting at home or run a small boutique, mini or hand-operated knitting machines offer an affordable and simple solution.

Perfect for: DIY crafters, home businesses

Use Case: Scarves, caps, baby clothes

Bonus: Portable and easy to use

10. Jacquard Knitting Machine – Best for Pattern-Heavy, Decorative Work

For brands that need complex patterns, logos, or textures in their fabric, Jacquard Knitting Machines are ideal. Though expensive, they allow high-resolution pattern control and multi-color output.

Perfect for: Branded wear, uniforms, fashion apparel

Strength: Pattern-rich, multi-color designs

Use Case: High-end knitwear

Final Thoughts

India’s textile industry is booming, and the right knitting machine can help you stay ahead of demand—whether you’re focused on high-volume production or artisanal design. If you’re just starting, consider the Single Jersey or Flat Knitting Machine. For large factories, Circular and Rib Knitting Machines deliver unmatched speed and efficiency.

Each machine type has its own niche, so evaluate your production needs carefully before making a purchase.

Need help choosing a knitting machine for your business? Drop a request or message, and we’ll guide you with tailor-made recommendations!

One Reply to “10 Best Knitting Machines in India for Industrial and Commercial Use”