Circular knitting machines have revolutionized the textile industry by making it easier, faster, and more consistent to produce tubular fabrics, the kind used in socks, mittens, sweaters, and more. These machines come in various diameters and configurations based on end-use, whether industrial-scale production or smaller specialty items.

In this guide, we’ll break down how circular knitting machines work, highlight the magic loop technique, and explain the different and best knitting machines in India used in the industry today.

How Circular Knitting Machines Work

Circular knitting machines are designed to knit fabric in a continuous circular motion, producing seamless tubes of material. The needles and sinkers are arranged in a circular bed, and long circular needles are used to create the desired looped structure. These machines are perfect for producing items like:

- Socks

- Gloves

- Sweater sleeves

- Tubular scarves

Double-bed circular knitting machines can knit forward on one bed and backward on the second, producing a complete tubular structure. For fine work like sock knitting, latch-hook needles are employed to ensure each stitch is formed accurately within the round frame.

A Look Back: From Hand-Knit to Machine Precision

Traditionally, sweaters and similar garments were hand-knitted in a circular form. Openings for sleeves, necklines, or button bands were created by adding extra stitches—these were later cut and reinforced using sewing machines. Today, circular knitting machines replicate this entire process with precision, speed, and far less manual labor.

Types of Circular Knitting Machines

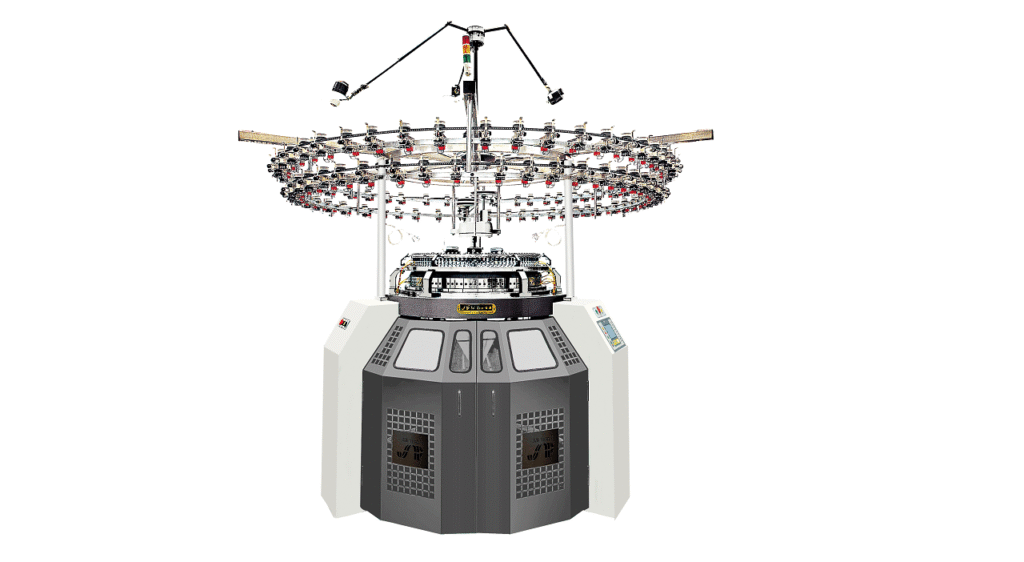

Understanding the types of circular knitting machines is key to selecting the right one for your production needs. There are two types of circular knitting machine given below with pictures with their sub-types:

1. Single Jersey Circular Knitting Machine

Single Jersey Circular Knitting machine is the most common type used in the textile industry.

- Structure: Consists of a single cylinder with one set of needles and sinkers.

- Fabric Output: Creates single jersey fabric, which has one smooth face and one textured back.

- Diameter: Usually around 30 inches but varies based on application.

- Applications: T-shirts, sportswear, base layers.

Advantages:

- Lightweight and breathable fabrics

- Cost-efficient production

- Easy to operate and maintain

2. Double Jersey Circular Knitting Machine

Double jersey machines produce thicker, stronger fabrics compared to single jersey machines.

- Structure: Includes two needle beds—one on the cylinder and one on the dial (no sinkers).

- Sub-types:

- Rib Circular Knitting Machine

- Interlock Circular Knitting Machine

- Fabric Output: Thicker fabrics with greater elasticity and durability.

- Applications: Sweaters, winter wear, outerwear, leggings.

Advantages:

- Enhanced stretch and recovery

- Double-sided usability

- Stronger, more structured fabric

Why Choose Bharat Machinery Works for Circular Knitting Machines?

At Bharat Machinery Works, we specialize in top-quality circular knitting machines for global clients. Whether you’re a small manufacturer or a large-scale factory, we offer machines that combine:

- Durability

- High-speed performance

- Minimal maintenance

- Affordable pricing

We proudly serve customers in Ethiopia, Rwanda, South Africa, and beyond. Our machines are built to perform for years, giving you unmatched value in productivity and quality.ded and it will work for a longer time. So, don’t think just get it now!

2 Replies to “Types of Circular Knitting Machine with Pictures”