Knitting, one of the oldest textile arts, has evolved significantly with the rise of modern knitting machines. Today, two dominant knitting techniques, weft knitting and warp knitting, are widely used in fabric production. Whether you’re a textile student, fashion designer, or industrial manufacturer, understanding the difference between weft and warp knitting is key to choosing the right method for your fabric needs.

In this article, we’ll break down both knitting styles, their structures, stitch types, advantages, and how the warp and weft direction affects fabric behavior, while also integrating industry-relevant terms like warp knit fabric examples and types of weft knitting.

What Is the Main Difference Between Weft and Warp Knitting?

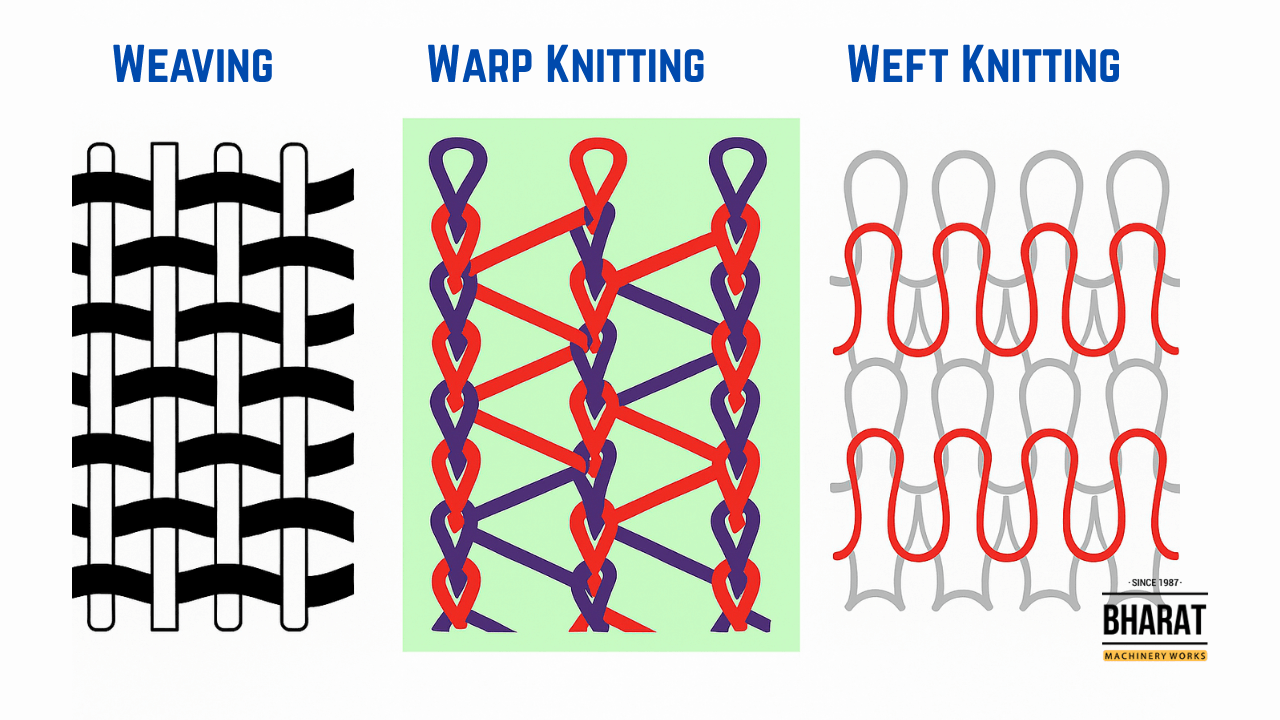

At a structural level, weft knitting uses a single yarn that loops horizontally (side to side), while warp knitting uses multiple yarns that loop vertically (up and down). This difference in warp and weft direction plays a crucial role in how the fabric behaves, feels, and functions.

| Feature | Weft Knitting | Warp Knitting |

|---|---|---|

| Yarn Direction | Horizontal (weft direction) | Vertical (warp direction) |

| Yarn Requirement | Single continuous yarn | Separate yarn for each needle |

| Machine or Hand | Machine and hand both | Only by machine |

| Fabric Type | Stretchy, drapey | Stable, coarse |

| Shrinkage | More prone to shrink | Shrink-resistant |

| Common Use | Garments, circular knits | Sportswear, lingerie, upholstery |

What Is Weft Knitting?

Weft knitting is a versatile knitting technique where the yarn runs in the weft direction, i.e., from left to right across the fabric. It can be done by hand or by machine and is commonly used to make flexible, soft, and elastic fabrics.

Characteristics of Weft Knitting:

- Uses a single continuous yarn.

- Easier to unravel if a loop breaks.

- Ideal for shaped garments like T-shirts, sweaters, and socks.

- Often used in circular knitting machines.

- Prone to shrinkage — handwashing recommended.

Common Types of Weft Knitting:

- Plain Stitch (Stockinette) – Smooth on one side, bumpy on the other.

- Rib Stitch – Alternates knit and purl stitches, offering excellent elasticity.

- Purl Stitch – Reversed version of the plain stitch, same texture on both sides.

These stitch types are foundational to hand knitting and fashion design.

Also Read: 10 Best Knitting Machines in India for Industrial and Commercial Use

What Is Warp Knitting?

Warp knitting is performed exclusively using machines, where multiple yarns run in the warp direction, i.e., lengthwise across the fabric. Each needle in the machine is fed its own yarn to create vertical loops that interlock in a zig-zag fashion.

Characteristics of Warp Knitting:

- Each needle uses its own yarn.

- Cannot be done by hand.

- Produces strong, stable, and durable fabrics.

- Faster production speed — ideal for mass production.

- Less prone to shrinkage, often machine-wash safe.

Common Warp Knit Fabric Examples:

- Tricot – Lightweight and soft; used in lingerie and linings.

- Raschel – Used for lace, net, and mesh fabrics.

- Simplex – Dense and thick, used for structured garments.

- Milanese – Smooth with a sheen, used in outerwear.

- Crochet Knit – Machine simulation of hand-crocheted fabric.

- Ketten Raschel – Raised patterns for upholstery and fancywear.

Understanding Warp and Weft Direction in Fabric

In both weaving and knitting, “warp” and “weft” refer to thread direction — but in knitting, these terms relate to how yarns form loops.

- In weft knitting, yarn runs side to side (weft direction), forming rows called courses.

- In warp knitting, yarn runs up and down (warp direction), forming columns called wales.

This distinction affects:

- Fabric stretch – weft knit fabrics stretch more.

- Strength and durability – warp knit fabrics hold shape better.

- Ease of unraveling – weft knits unravel easily, warp knits don’t.

Which Is Better: Weft or Warp Knitting?

It depends on the intended use:

Choose weft knitting if you need:

- High elasticity

- Shaped or fitted garments

- A wide range of knitting styles

- Delicate or soft textures

Choose warp knitting if you need:

- High production speed

- Durable, coarse fabrics

- Machine-wash safe textiles

- Fabrics for industrial or technical use

Know Your Knitting to Choose the Right Machine

Understanding the difference between warp and weft knitting isn’t just textbook knowledge — it’s a critical decision-maker for manufacturers, designers, and hobbyists. Whether you’re choosing the right machine, developing a new product line, or experimenting with fabric behavior, the warp and weft direction will shape your results.

Why Choose Us for Your Knitting Machine Needs?

At Bharat Machinery Works, we are proud to be a leading knitting machine manufacturer in Ludhiana, delivering world-class machines for both weft and warp knitting needs. Our machines are equipped with cutting-edge features, offer high durability, and maximize your production output.

From circular knitting machines to warp-knit-specific devices, we help you select the right equipment to match your project requirements. Our clients trust us not only for premium machinery but also for our expertise, guidance, and after-sales service.

Contact us today to learn more about our knitting solutions!